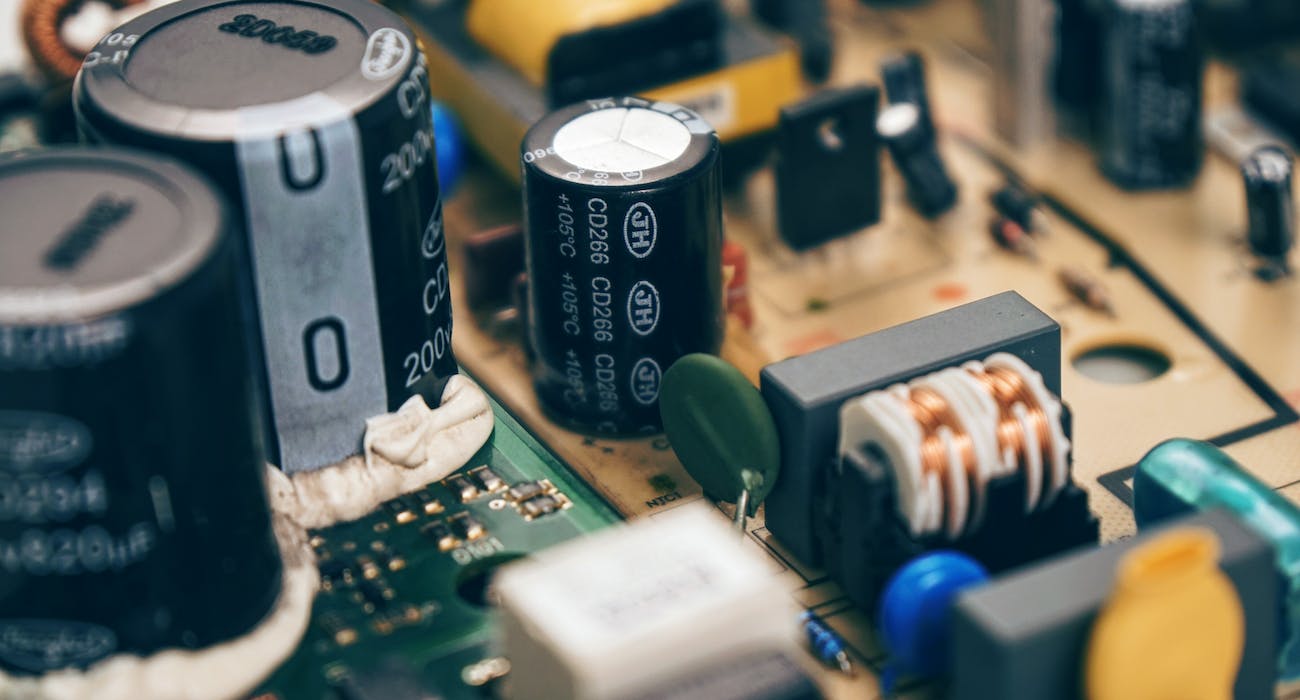

The electronics industry is known for its rapid advancements and innovations. To stay competitive and meet growing demand, electronics businesses often face the challenge of scaling up their production efficiently. Contract manufacturing services have emerged as a strategic solution for electronics companies looking to expand their operations, streamline production, and enhance their market presence. This article explores how contract electronics manufacturing services can be the key to scaling up your electronics business.

Cost Efficiency: Minimising Capital Expenditure

One of the primary advantages of contract manufacturing is cost efficiency. Electronics businesses can save significant capital by outsourcing production to contract manufacturers. This eliminates the need for investing in expensive manufacturing facilities, equipment, and the hiring and training of additional personnel.

Customisation and Diversification: Meeting Diverse Needs

Contract manufacturers can adapt to the unique needs of different electronics businesses. They can handle a wide range of products, from simple electronic components to complex, customised devices. This versatility enables electronics companies to diversify their product offerings and enter new markets.

Expertise and Specialisation: Accessing Technical Proficiency

Contract manufacturers specialise in electronic assembly and have extensive technical expertise. They stay up-to-date with the latest industry trends, materials, and manufacturing techniques. Partnering with a contract manufacturer means gaining access to this specialised knowledge and ensuring high-quality production.

Reduced Time-to-Market: Speeding Up Product Launches

Time-to-market is critical in the electronics industry. Contract manufacturing can significantly reduce the time required to launch new products. Contract manufacturers often have streamlined processes and can quickly adapt to production changes, helping businesses get their products to market faster.

Quality Assurance: Ensuring Product Excellence

Many companies rely on advanced electronics manufacturing solutions to bring their innovative products to life with precision and efficiency. Reputable contract manufacturers implement stringent quality assurance measures and adhere to industry standards. This commitment to quality ensures that the products manufactured meet or exceed customer expectations.

Focus on Core Competencies: Strategic Resource Allocation

Outsourcing production to contract manufacturers allows electronics companies to focus on their core competencies, such as research and development, marketing, and innovation. This strategic resource allocation enables businesses to grow and innovate without being burdened by manufacturing logistics.

Cost Predictability: Managing Expenses

With contract manufacturing, businesses can predict their manufacturing costs more accurately. This helps in budgeting and financial planning, as contract manufacturers often provide fixed pricing structures, reducing the risk of unexpected expenses.

Long-Term Partnership: Building Relationships

A successful partnership with a contract manufacturer can extend beyond a single project. Long-term relationships can be built, fostering collaboration, trust, and mutual growth. Such partnerships often result in increased efficiency and shared success.

Global Reach: Accessing Worldwide Markets

Contract manufacturing services often extend beyond national borders. Many contract manufacturers have a global presence, allowing electronics companies to tap into international markets and benefit from cost-effective manufacturing facilities in various regions.

Supply Chain Optimisation: Streamlining Procurement

Contract manufacturers often have established relationships with suppliers, allowing them to procure components and materials more efficiently. This streamlines the supply chain, reduces lead times, and minimises the risk of component shortages, which can be particularly beneficial in times of high demand or supply chain disruptions.

Innovation and Technology Adoption: Staying Current

The electronics industry evolves rapidly, with new technologies and manufacturing processes emerging regularly. Contract manufacturers often invest in the latest equipment and technologies to remain competitive. Partnering with them allows electronics businesses to leverage cutting-edge innovations without the need for significant capital investment.

Conclusion

Scaling up an electronics business requires a strategic approach to production and resource allocation. Contract electronics manufacturing services offer a compelling solution. By partnering with a reputable contract manufacturer, electronics companies can focus on innovation and core competencies while ensuring the production of high-quality electronic products. In a dynamic and competitive industry, contract manufacturing can be the key to achieving growth, success, and global reach.